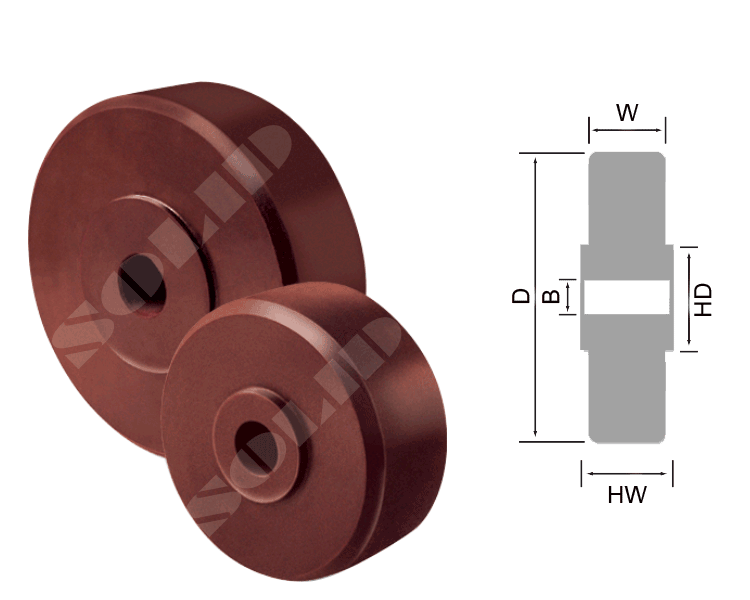

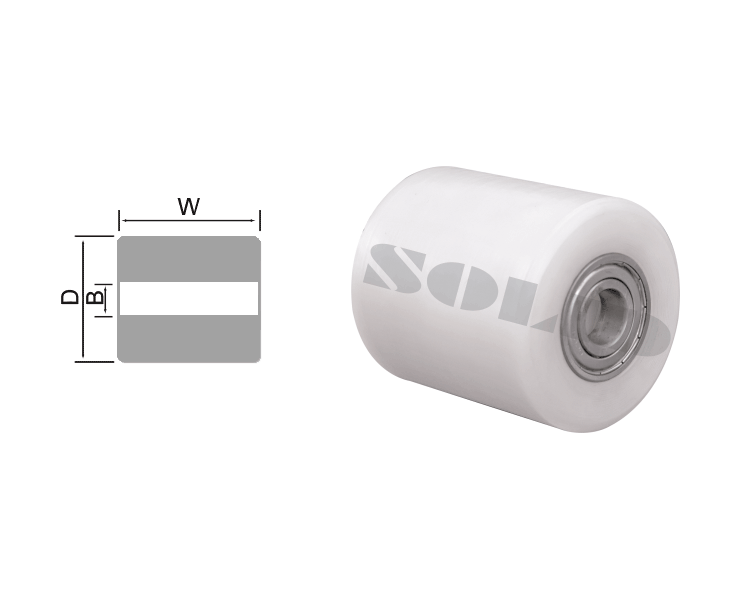

UHMW-PE Wheels

These wheels are manufactured from Ultra High Molecular Weight Poly Ethylene (UHMW-PE) material. Self lubricating material. These wheels have very high load carrying capacity, high impact strength and high wear resistance; hence it does not crack under shock of impact load as it happens in nylon or fiber wheels. The material has got very low co-efficient of friction, hence pulling or pushing efforts required are less. The material does not have effect of chemical and acids. This material is not hard like cast iron hence these wheels does not damage the floor.

These wheels are molded under controlled temperature and pressure in accurately formed close fitting molds for unique strength and toughness. These are made by compression molding process.

Available Sizes

|

|

|

|

|

|

|---|---|---|---|---|---|

| 75 | 25 | 12 | 28 | 24 | 125 |

| 75 | 32 | 12 | 35 | 24 | 150 |

| 75 | 38 | 12 | 41 | 24 | 180 |

| 100 | 25 | 12 | 30 | 41 | 210 |

| 100 | 32 | 16 | 37 | 41 | 250 |

| 100 | 38 | 16 | 43 | 41 | 265 |

| 100 | 50 | 19 | 55 | 41 | 300 |

| 125 | 38 | 19 | 44 | 72 | 375 |

| 125 | 50 | 25 | 56 | 72 | 415 |

| 150 | 38 | 19 | 43 | 73 | 500 |

| 150 | 50 | 25 | 55 | 73 | 600 |

| 150 | 75 | 25 | 80 | 73 | 840 |

| 180 | 50 | 25 | 55 | 70 | 750 |

| 200 | 50 | 25 | 56 | 72 | 1100 |

| 200 | 62 | 25 | 68 | 72 | 1275 |

| 200 | 75 | 25 | 81 | 72 | 1350 |

| 250 | 50 | 25 | 55 | 80 | 1225 |

| 250 | 62 | 25 | 67 | 80 | 1400 |

| 250 | 75 | 25 | 80 | 80 | 1575 |

| 300 | 50 | 25 | 56 | 87 | 1320 |

| 300 | 62 | 25 | 68 | 87 | 1470 |

| 300 | 75 | 25 | 81 | 87 | 1620 |

| 300 | 85 | 25 | 91 | 87 | 1850 |

Available Sizes

|

|

|

|

|

|

|---|---|---|---|---|---|

| 75 | 25 | 12 | 28 | 24 | 125 |

| 75 | 32 | 12 | 35 | 24 | 150 |

| 75 | 38 | 12 | 41 | 24 | 180 |

| 100 | 25 | 16 | 30 | 41 | 210 |

| 100 | 32 | 16 | 37 | 41 | 250 |

| 100 | 38 | 16 | 43 | 41 | 265 |

| 100 | 50 | 19 | 55 | 41 | 300 |

| 125 | 38 | 19 | 44 | 72 | 375 |

| 125 | 50 | 25 | 56 | 72 | 415 |

| 150 | 38 | 19 | 43 | 73 | 500 |

| 150 | 50 | 25 | 55 | 73 | 600 |

| 150 | 75 | 25 | 80 | 73 | 840 |

| 180 | 50 | 25 | 55 | 70 | 750 |

| 200 | 50 | 25 | 56 | 72 | 1100 |

| 200 | 62 | 25 | 68 | 72 | 1275 |

| 200 | 75 | 25 | 81 | 72 | 1350 |

| 250 | 50 | 25 | 55 | 80 | 1225 |

| 250 | 62 | 25 | 67 | 80 | 1400 |

| 250 | 75 | 25 | 80 | 80 | 1575 |

| 300 | 50 | 25 | 56 | 87 | 1320 |

| 300 | 62 | 25 | 68 | 87 | 1470 |

| 300 | 75 | 25 | 81 | 87 | 1620 |

| 300 | 85 | 25 | 91 | 87 | 1850 |

| 350 | 50 | 25 | 56 | 100 | 1450 |

| 350 | 62 | 25 | 68 | 100 | 1580 |

| 350 | 75 | 25 | 81 | 100 | 1750 |

| 400 | 50 | 30 | 56 | 100 | 1600 |

| 400 | 62 | 30 | 68 | 100 | 1740 |

| 400 | 75 | 30 | 81 | 100 | 1940 |

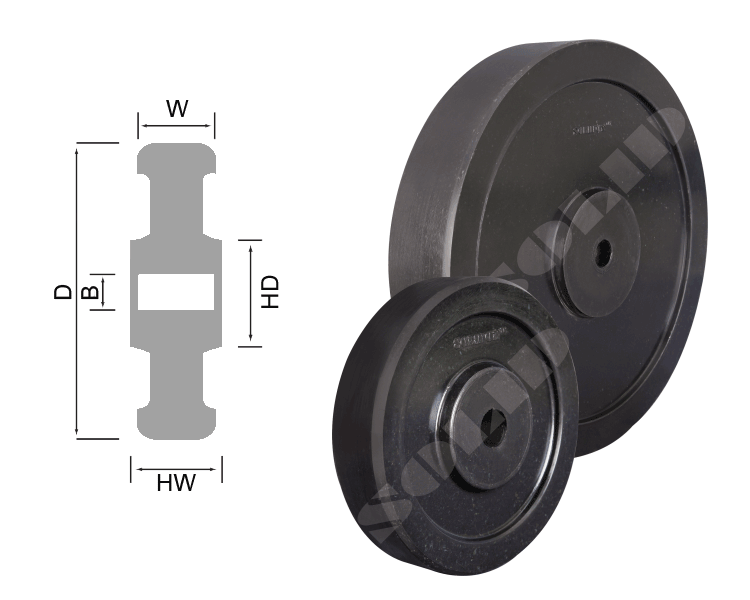

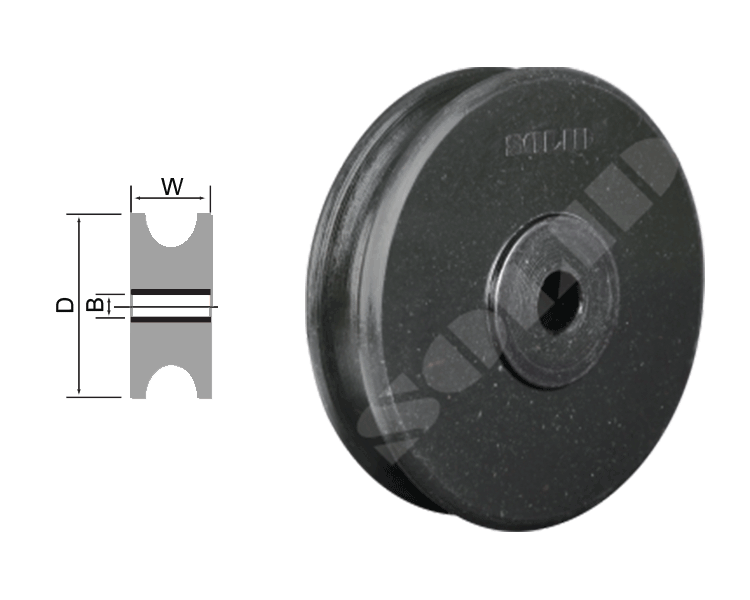

UHMW-PE Wheels With C.I. Hub Inserted During Molding Or Metal Insert For Ball Bearings.

As UHMW-PE has got very low co-efficient of Friction, ball bearing has tendency to rotate in the step bore. To avoid this, C. I. Hub inserted during molding or metal insert is pressed in the wheel. C. I. Hub or metal insert have step bore suitable for required ball bearings.

Available Sizes

|

|

|

|

|

|

|---|---|---|---|---|---|

| 75 | 25 | 12 | 27 | 24 | 100 |

| 75 | 32 | 12 | 34 | 24 | 125 |

| 75 | 38 | 12 | 40 | 24 | 150 |

| 100 | 32 | 16 | 35 | 35 | 190 |

| 100 | 38 | 16 | 41 | 35 | 220 |

| 100 | 50 | 19 | 53 | 35 | 250 |

| 125 | 38 | 19 | 41 | 50 | 280 |

| 125 | 15 | 25 | 53 | 50 | 350 |

| 150 | 38 | 25 | 43 | 73 | 445 |

| 150 | 50 | 25 | 53 | 67 | 525 |

| 150 | 75 | 25 | 78 | 67 | 700 |

| 200 | 50 | 25 | 55 | 70 | 700 |

| 200 | 75 | 25 | 80 | 70 | 1000 |

| 250 | 50 | 25 | 55 | 77 | 825 |

| 250 | 62 | 25 | 67 | 77 | 1000 |

| 250 | 75 | 25 | 80 | 77 | 1175 |

| 300 | 50 | 25 | 55 | 88 | 900 |

| 300 | 62 | 25 | 67 | 88 | 1050 |

| 300 | 75 | 25 | 80 | 88 | 1300 |

| 300 | 85 | 25 | 90 | 88 | 1425 |

Available Sizes

|

|

|

|

|

|

|---|---|---|---|---|---|

| 100 | 32 | 16 | 34 | 35 | 175 |

| 100 | 38 | 16 | 40 | 35 | 200 |

| 100 | 50 | 19 | 52 | 35 | 270 |

| 150 | 50 | 25 | 54 | 69 | 475 |

| 150 | 75 | 25 | 79 | 69 | 545 |

| 180 | 50 | 25 | 60 | 78 | 675 |

| 200 | 50 | 25 | 60 | 78 | 730 |

| 200 | 75 | 25 | 85 | 78 | 900 |

| 250 | 50 | 25 | 55 | 77 | 825 |

| 250 | 62 | 25 | 67 | 77 | 1000 |

| 250 | 75 | 25 | 80 | 77 | 1175 |

| 300 | 50 | 25 | 55 | 88 | 900 |

| 300 | 62 | 25 | 67 | 88 | 1050 |

| 300 | 75 | 25 | 80 | 88 | 1300 |

| 300 | 80 | 25 | 90 | 88 | 1425 |

Available Sizes

|

|

|

|

|---|---|---|---|

| 75 To 85 | 65 | 30 | 760 |

| 75 To 85 | 70 | 30 | 825 |

| 75 To 85 | 75 | 30 | 890 |

| 75 To 85 | 80 | 30 | 955 |

| 75 To 85 | 85 | 30 | 1020 |

| 75 To 85 | 90 | 30 | 1085 |

| 75 To 85 | 955 | 30 | 1150 |

| 75 To 85 | 100 | 30 | 1215 |

| 75 To 85 | 105 | 30 | 1280 |

| 75 To 85 | 110 | 30 | 1350 |

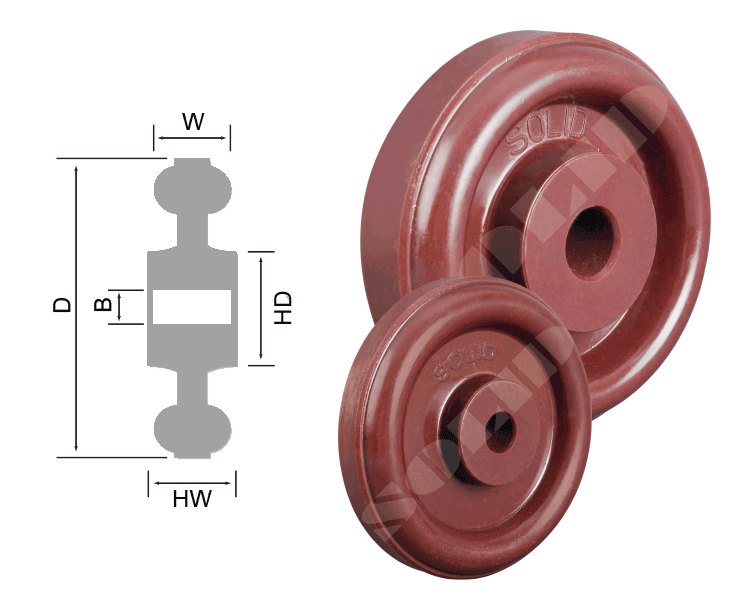

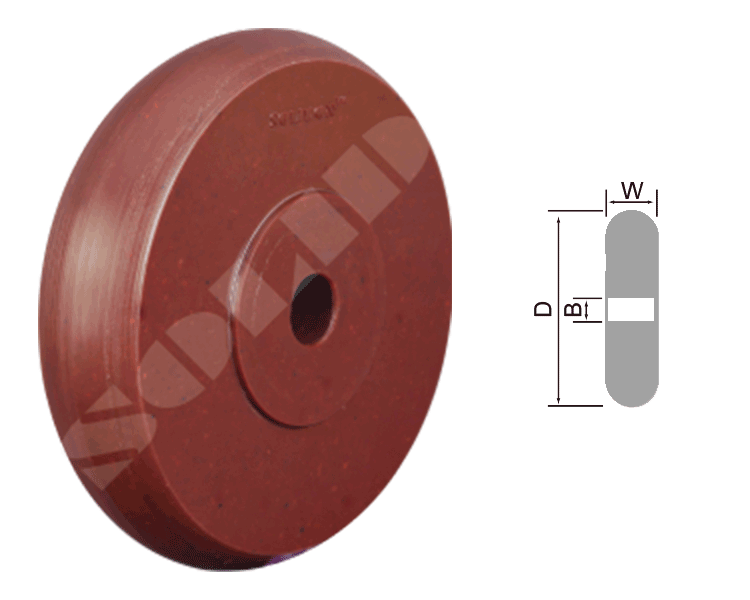

Series 905

Series 905 are fabricated from Series 901 wheels, hence all specifications remain the same as that of Series 901.

Product Inquiry!

Available Sizes

|

|

|

|

|

|

|---|---|---|---|---|---|

| 75 | 25 | 12 | 28 | 24 | 125 |

| 75 | 32 | 12 | 35 | 24 | 150 |

| 75 | 38 | 12 | 41 | 24 | 180 |

| 100 | 25 | 12 | 30 | 41 | 210 |

| 100 | 32 | 16 | 37 | 41 | 250 |

| 100 | 38 | 16 | 43 | 41 | 265 |

| 100 | 50 | 19 | 55 | 41 | 300 |

| 125 | 38 | 19 | 44 | 72 | 375 |

| 125 | 50 | 25 | 56 | 72 | 415 |

| 150 | 38 | 19 | 43 | 73 | 500 |

| 150 | 50 | 25 | 55 | 73 | 600 |

| 150 | 75 | 25 | 80 | 73 | 840 |

| 180 | 50 | 25 | 55 | 70 | 750 |

| 200 | 50 | 25 | 56 | 72 | 1100 |

| 200 | 62 | 25 | 68 | 72 | 1275 |

| 200 | 75 | 25 | 81 | 72 | 1350 |

| 250 | 50 | 25 | 55 | 80 | 1225 |

| 250 | 62 | 25 | 67 | 80 | 1400 |

| 250 | 75 | 25 | 80 | 80 | 1575 |

| 300 | 50 | 25 | 56 | 87 | 1320 |

| 300 | 62 | 25 | 68 | 87 | 1470 |

| 300 | 75 | 25 | 81 | 87 | 1620 |

| 300 | 85 | 25 | 91 | 87 | 1850 |

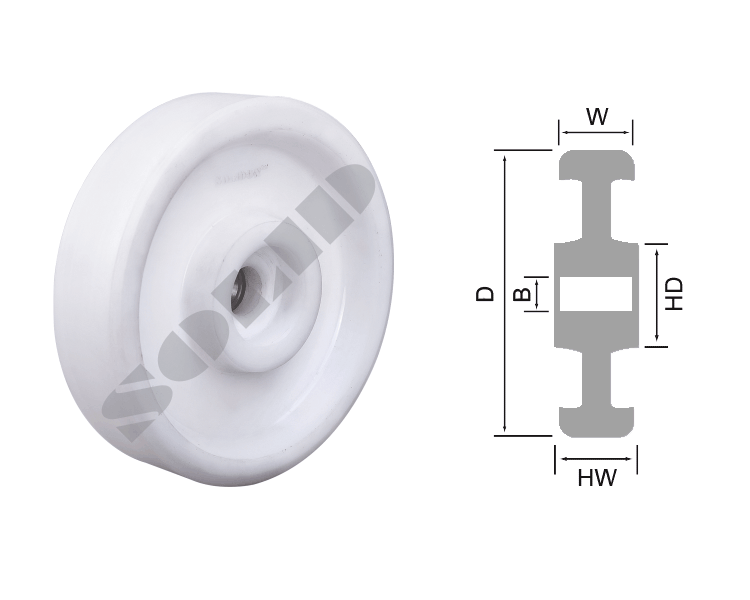

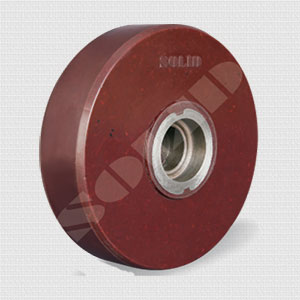

Rope Pulleys Series 906 are made from UHMW – PE Material but with special process.

Hardness: (70 +/- 5) shore D scale

Max – Working Temp: 110°C

Break Elongation: 450%

Density: 0.94 GR/Cm3

Tensile Strength: 440 Kg/Cm3

Abrasion Loss: Min.3-8 mm3 / 100 SW

Impact Strength [Notch]: No Break

Please refer our CodeWords & Symbols Guide for detailed understanding on Product Series, Codes, Symbols, Material Comparison, Wheel Series Examples & Abbreviations.

Wheels

Casters

S. S. Casters